Page 102 - 360.revista de Alta Velocidad - Nº 5

P. 102

Meyer zu Hörste, Michael. Asbach, Lennart. Hardi, Hungar. Lemmer, Karsten.

trains. These data can be easily reused for testing the ATO systems. I.e. huge number of tests

can be defined by using the real data and the trust in the systems can be maximized and a

comprehensive testing for ATO on functional interfaces can be assured easily.

4. Interface Conformity of digitalized track-side equipment

4.1 Digitalization of track-side equipment

The general approach of constructing executable test sequences from generic test cases is

equally well suited for the conformity test of track-side equipment as it is for testing on-board

components. What is different with track-side equipment is the lesser degree of standardisation:

Interfaces and even functional architectures may differ, depending on the manufacturer.

To improve compatibility, an approach currently employed by the German Railways is to

incrementally specify the interface behaviour of equipment components. I.e., only some of the

interfaces of an interlocking system are specified (and shall be tested), while others remain to

be considered somewhen in the future. The reason is that it is easier to specify and implement

a standard version of the focus interface, and not having to come up with a formalisation and

re-implementation of the full system.

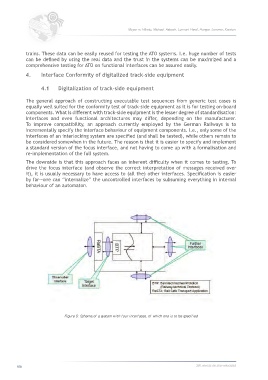

The downside is that this approach faces an inherent difficulty when it comes to testing. To

drive the focus interface (and observe the correct interpretation of messages received over

it), it is usually necessary to have access to (all the) other interfaces. Specification is easier

by far--one can “internalize” the uncontrolled interfaces by subsuming everything in internal

behaviour of an automaton.

Figure 5: Schema of a system with four interfaces, of which one is to be specified

100 360.revista de alta velocidad